Sheffield Hallam University (SHU)

The National Centre of Excellence for Food Engineering at Sheffield Hallam University offers extensive industry knowledge, pioneering technical expertise and cutting-edge facilities to help both large manufacturers and smaller independent businesses throughout the supply chain to meet the challenges facing the industry today.

The National Centre of Excellence for Food Engineering at Sheffield Hallam University offers extensive industry knowledge, pioneering technical expertise and cutting-edge facilities to help both large manufacturers and smaller independent businesses throughout the supply chain to meet the challenges facing the industry today.

At the Centre, we are led by the principles of Engage, Enable, Engineer. Using these principles, we work with you to improve business performance and solve real life challenges whether it's improving system and process efficiency, reducing waste saving energy or improving product quality and composition.

Some of our projects are:

- Nestlé – effective milk processing with variable composition

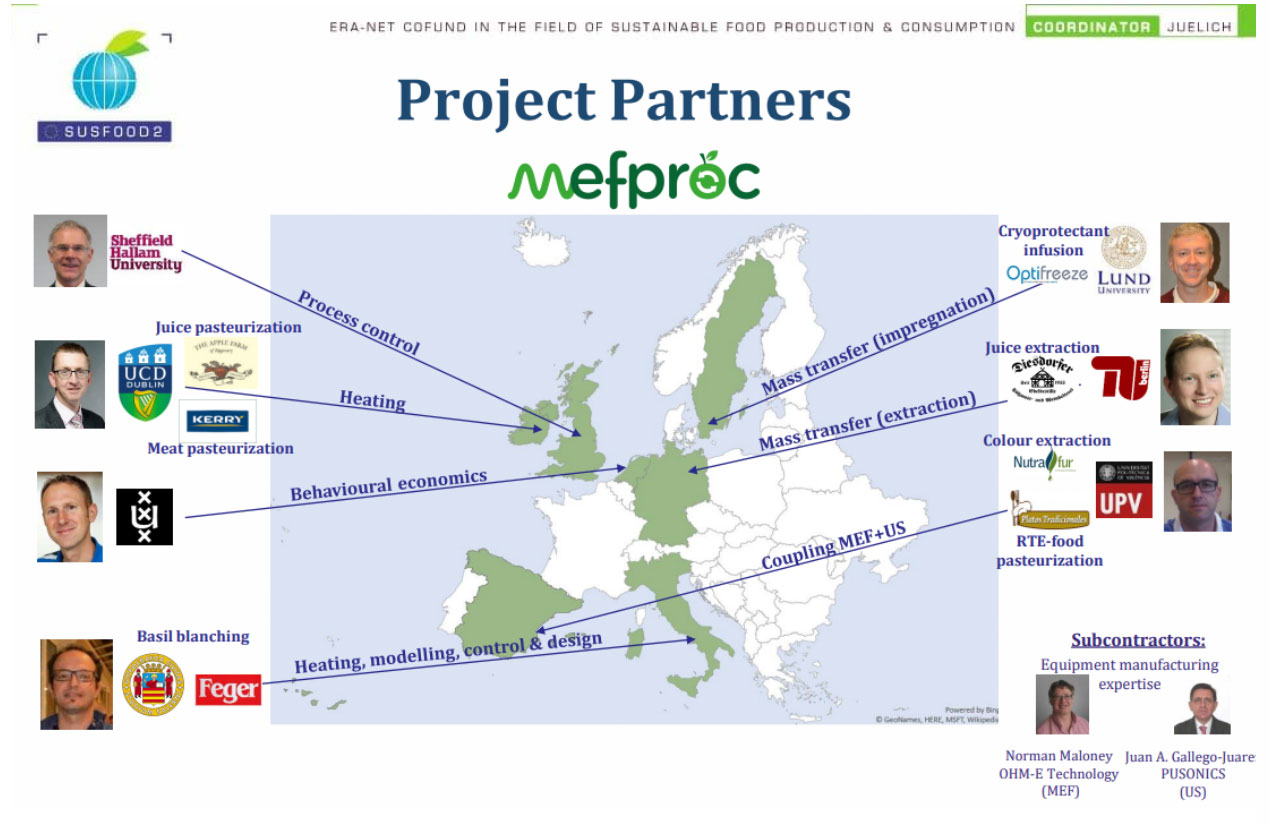

- MEFPROC – producing microbiologically safe products within the European Food Industry

- Nestlé Heat Recovery – reducing energy loss in baking processes

- Royal Academy of Engineering Newton Research Collaboration programme

- Dext Heat Recovery – advanced heat recovery systems for food manufacturing

- Greencore – reducing salt and fat content of baked cheese products

- Koolmill – enhanced rice milling and maximised valorisation of rice milling by products

- World Feeds – Knowledge Transfer Partnership

- Valorisation of industrial garlic waste

Areas of research focus in MEFPROC project:

This project will explore ohmic heating in different applications such as pasteurisation, blanching and sterilisation. The mathematical and physical models will be developed using a combination of MATLAB/SIMULINK and COMSOL software. The application of advanced control systems based on the models developed will be carried out. Advanced process control methods such as PID, auto-tuning PID controllers, Model Predictive Control (MPC) and Multivariate Statistical Process Control (MSPC) will be designed and applied to for more effective control of the process parameters including electrical conductivity, thermal conductivity, food particle size and viscosity which may change at different times. Also, the analysis of energy efficiency involved in process control and the choice of controller to achieve better efficiency will be conducted. This method provides an avenue for easy transition between designed controllers based on evaluated performance. The influence of the process parameters on the ohmic heater operation using MEF will be studied.

Contact address

National Centre of Excellence for Food Engineering

Sheffield Hallam University

811 Attercliffe Rd

Sheffield

S9 2AA

0114 225 5000

(opens in a new window)business@shu.ac.uk

Martin Howarth

(opens in a new window)howarth@shu.ac.uk

Director, National Centre of Excellence for Food Engineering

Hongwei Zhang

Deputy Head of Department, Engineering and Mathematics

(opens in a new window)Zhang@shu.ac.uk

Università degli Studi di Salerno (UNISA)

The University of Salerno is one of the most modern and dynamic academic institutions in Italy, one of the few universities organized in campus; the main one (hosting 16 departments, interdepartmental centres, public and private research consortia, some sport facilities, canteens , students dormitories and guest houses) being in the town of Fisciano and the second one (hosting the School of Medicine and some sport facilities) being in the town of Baronissi, both located a few kilometers from Salerno, and the second campus in Baronissi.

The University of Salerno is one of the most modern and dynamic academic institutions in Italy, one of the few universities organized in campus; the main one (hosting 16 departments, interdepartmental centres, public and private research consortia, some sport facilities, canteens , students dormitories and guest houses) being in the town of Fisciano and the second one (hosting the School of Medicine and some sport facilities) being in the town of Baronissi, both located a few kilometers from Salerno, and the second campus in Baronissi.

A wide range of undergraduate and postgraduate courses are offered to students from across Italy and the wider world. The university also offers a number of double-degrees in collaboration with partners from around the world.

The Industrial Engineering department at the University of Salerno is widely involved in undergraduate and post graduate courses, and in a wide area of scientific research, covering chemical, electrical, electronic, food, management and mechanical engineering, with a focus on Industry 4.0.

Overview of the research activities

The research group involved in MEFPROC has a wide expertise in food processes assisted by electric/electro-magnetic fields (including microwave, ohmic and radio-frequency applications) and their simulation in virtual tools built by process modeling.

Over the years, the research group has been involved in innovative projects promoted by multinational companies.

Areas of research focus in MEFPROC project

In MEFPROC project, UNISA is involved in the design, assemble, model and control of MEF system which can be used in standalone configuration or integrated with ultrasound (US). A laboratory scale prototype MEF system will be developed and the effects MEF heating of sauces based on green leaves (pesto from basil) on the quality and sensorial properties of such food product will be investigated.

Contact address

Francesco Marra, PhD

Associate Professor of Transport Phenomena

Department of Industrial Engineering, University of Salerno

via Giovanni Paolo II 132, Fisciano SA 84084 Italy

phone: +39 089 96 2012

e-mail: (opens in a new window)fmarra@unisa.it

Website: (opens in a new window)https://www.unisa.it/

Universitat Politècnica de València (UPV)

The Universitat Politècnica de València (UPV) is a public, dynamic and innovative institution dedicated to research and teaching that, while maintaining strong bonds with the social environment in which it carries out its activities, advocates for a solid presence abroad. It is a young university, which celebrated its 50th anniversary during the 2018-2019 academic year.

The Universitat Politècnica de València (UPV) is a public, dynamic and innovative institution dedicated to research and teaching that, while maintaining strong bonds with the social environment in which it carries out its activities, advocates for a solid presence abroad. It is a young university, which celebrated its 50th anniversary during the 2018-2019 academic year.

Its community is made up of around 34,000 students, 3,600 lecturers and researchers and 1,500 administration and services professionals distributed among its three campuses located in Alcoi, Gandia and València.

At present, the UPV comprises 13 university centers, of which nine are higher technical schools, two are faculties and another two, higher polytechnic schools. In addition, it has a Doctoral School and three affiliated centres (Florida University, Berklee College of Music and EDEM Business School).

Overview of research activities of ASPA group (UPV)

The researchers of Universitat Politècnica de València involved in MEFPROC project are members of the research group ASPA (Analysis and Simulation of Agro-Food Processes), located in the Department of Food Technology. This group began its activities in 1991 and has as a main objective the analysis and optimization of agrofood processes (energy, environment, economics, production..). To this end, processes are characterized, designed and controlled by operation modelling and simulation using computer tools. Not only are conventional processes such as drying or thermal treatments considered, but new technologies like supercritical fluid extraction, high power ultrasonics and PEF and MEF are also investigated. Product assessment involves the classical physico-chemical analysis as well as the use of new techniques based on ultrasonics (non-destructive) or electromyography.

Areas of research focus in MEFPROC project

The participation of UPV in MEFPROC is mainly involved with the design and develop a high performance, flexible and reliable ultrasonic prototype and its integration in a MEF system. The combined (simultaneous or sequential) US and MEF application will be evaluated in volumetric heating or extraction/impregnation processes in terms of kinetics, quality of products and energy consumption. Modifications in the prototype will be considered to improve processing, the security or the feasibility to scale-up.

Lund University (LU)

Lund University, Department of Food technology, engineering and nutrition

Lund University, Department of Food technology, engineering and nutrition

A short overview of research activities

Our research covers experimental and theoretical areas to meet issues with relevance to the food industry, pharmaceutical industry and other related areas, as well as system aspects of food production and consumption in society.

Research with products in focus:

Food Technology, Food Chemistry and Formulation are areas that deal with the chemical description of molecular and colloidal properties, which illustrate relationships between biological processes, structure, and properties in composite systems such as food, pharmaceuticals and consumer goods.

Research with processes in focus:

Food and Dairy Engineering involve modeling, hydrodynamics, heat and mass transfer, optimization and function evaluation that are needed to design and optimize unit operations, processes and technical systems for food production. Dairy technology also includes the functional properties of milk systems and its process impact in the dairy industry.

Research with humans in focus:

Nutritional studies involve the impact of food components and diet on metabolism and other physiological functions of importance to human health. The health effects are studied in relation to the chemical and physical properties of food, as well as changes in the microflora of the intestine, composition and metabolism. Food hygiene, where the relationship between humans and microorganisms is in focus, addresses the benefits and risks created by microorganisms in our food.

Areas of your research focus in MEFPROC project

The Emerging Technologies group focuses on research on vacuum impregnation (VI) and two electro technologies: pulsed electric field (PEF) and moderate electric field (MEF) for the processing of fruit and vegetables. Emphasis is made on the use of these technologies for the improvement of freezing tolerance, improvement of quality of aromatic dried herbs and the prolongation of shelf life of fresh, packed vegetables. Fundamental research is also carried out on aspects of plant stress physiology related with the above-mentioned unit operations.

Contact address:

Naturvetarvägen 14,

SE-22100,

Lund,

Sweden.

Technische Universität Berlin (TUB)

The Technische Universität Berlin (TUB) is one of four universities in Berlin. Currently, TUB has 7830 employees and 360 professorships. About 35 000 students are enrolled in more than 120 study programs. Research activities are focusing on the six key application areas Digital Transformation; Energy Systems, Mobility, and Sustainable Resources; Human Health, Humanities, and Educational Science; Urban Systems and Environmental Systems; Photonics and Optical Systems, Materials, Design and Manufacturing

The Technische Universität Berlin (TUB) is one of four universities in Berlin. Currently, TUB has 7830 employees and 360 professorships. About 35 000 students are enrolled in more than 120 study programs. Research activities are focusing on the six key application areas Digital Transformation; Energy Systems, Mobility, and Sustainable Resources; Human Health, Humanities, and Educational Science; Urban Systems and Environmental Systems; Photonics and Optical Systems, Materials, Design and Manufacturing

Detail of research activities at TUB University:

The department of food biotechnology and food process engineering of TUB has more than 20 years of experience in innovative food processing including electric fields and high power ultrasound. Activities focus on mass transfer improvement, gentle preservation techniques, and stress induction for enhanced secondary metabolite production as well as process optimization via experimental and numerical approaches. A lot of research is performed within the field of fruit and vegetable processing in regard to product quality and process efficiency. The department has several units for electro- and ultrasound processing up to pilot plant scale as well as extensive equipment for processing and analysis of fruit material.

Areas of research focus in MEFPROC:

The task of TUB is to evaluate the potential of moderate electric fields (MEF) and high power ultrasound (US) to improve mass transport operations in fruit processing. Therefore, the entire process chain of fruit processing is regarded and the innovative technologies are applied in different stages of the process chain to figure out their optimal application areas. Apples and berries serve as raw materials. Investigations are performed in laboratory and pilot plant scale and results compared to conventional thermal treatments and high intensity electric pulses in regard to product quality and process efficiency.

The first step in the processing chain, in which MEF is applied, is the production of fruit juices. MEF treatment will be used to facilitate solid-liquid separation resulting in less press residue, and to increase the extraction of valuable vitamins and secondary metabolites during pressing to positively affect color and antioxidant properties of the fruit juice.

MEF effects are also used to improve extraction of pigments and secondary metabolites from fruit press cakes. Pectin recovery from by-products of juice manufacturing is usually performed at acid pH-values and high temperatures. Here, the application of MEF may be an effective alternative to indirect heating methods. Both extraction procedures may further be improved by the additional usage of ultrasound for enhanced mass transport.

The residual material remaining after pectin extraction is rich in insoluble dietary fibers which gain more and more interest as nutritional additives and techno-functional compounds in fat and sugar reduced food products. As techno-functionality of fibers exhibits marked shear sensitivity, application of ultrasound in previous processing stages may affect water binding capacity and rheological behavior of the plant fibers. The influence of MEF and US is therefore as well investigated with regard to functional fiber properties.

Contact address:

Dr. -Ing. Cornelia Rauh

Department of Food Biotechnology an

Food Process Engineering

Technische Universität Berlin

Koenigin-Luise-Str. 22

D-14195 Berlin

Tel: +49 30 314-71250

Fax: +49 30 832 76 63

e-mail: (opens in a new window)cornelia.rauh@tu-berlin.de